Facilities: Processing Equipment

Extrusion foaming lines:

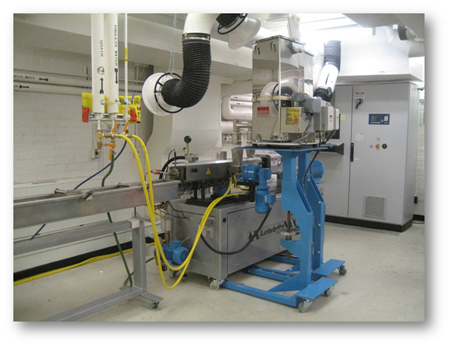

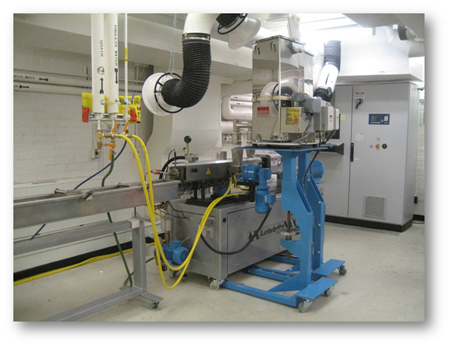

– 2.5’’(44L/D) single-screw foaming extruder

– 1.5’’-2.5’’ tandem foaming extruder: This system exhibits very effective plasticization and cooling of the polymer melt to achieve homogenous polymer-gas mixture for foaming.

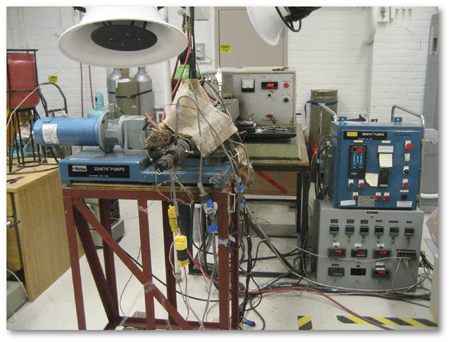

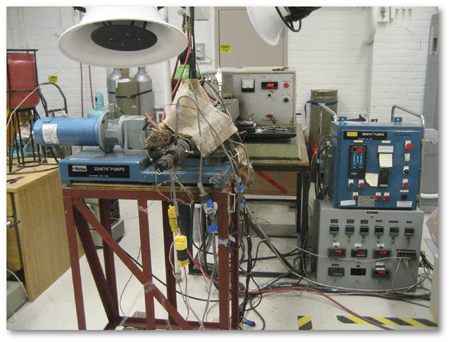

– 0.75’’-1.5’’ tandem foaming extruder

– 0.75’’ single-screw foaming extruder: This small-scale system is ideal for conducting pilot runs of new foaming processes.

Injection foam molding machines

– 50 ton MuCell injection molding machine

1 27mm twin-screw compounder: This system compounds polymer and additives efficiently with a high throughput.

1 EPP/EPS bead foaming system

1 rotational molding machine

2 compression molding machines

5 batch foaming apparatuses

1 batch mixer

|